Engineering Design Intent from Concept to Production

With over 30 years of experience providing product engineering services across industries from sporting goods to medical devices, our engineers can help augment your team, or act as your full product development engineering team.

Engineers work alongside our in-house team of designers, integrated throughout the entire process — from early brainstorm through manufacturing handoff. When engineering development is approached holistically, the result is a unified solution rather than a mash up of pieces that don’t flow together. Ideas turn into realistic solutions that can be made with fewer revisions along the way, keeping the original design intent in the final product.

Diverse Engineering Teams Collaborate on Multi-Faceted Projects

Ultimately, we worked with Priority Designs because we really needed some rigor and expertise that we weren’t going to get as turnkey with some of the other partners. It was clear that the capabilities of the in-house team could handle the mechanical, industrial design and electrical work which was a strength over and above other firms.

Brand Director

Scotts Miracle-Gro

Ultimately, we worked with Priority Designs because we really needed some rigor and expertise that we weren’t going to get as turnkey with some of the other partners. It was clear that the capabilities of the in-house team could handle the mechanical, industrial design and electrical work which was a strength over and above other firms.

Brand Director

Scotts Miracle-Gro

Engineering Services

Whether You Need Us From Start to Finish or Just One Step, Here's How We Can Help:

Product Ideation

Early on in the process, engineers work alongside design teams on product ideation and brainstorm sessions. With experience across industries, we develop innovative solutions that cross-pollinate ideas from other industries, providing new solutions in unexpected ways. At this stage, engineers weigh in on material selection and preliminary considerations for manufacturing. Initial ideas may start with quick, rough proof-of-concept prototypes to validate before moving further with a design concept.

Software Tools

It is important to verify software compatibility and constraints with our clients to ensure a seamless transition between our engineers and your company’s development team. We know not every client uses the same tool, and we aim to stay flexible to use the right tool for you.

CAD Packages:

– Solidworks (and Solidworks PDM)

– Creo

– Catia

Analysis Software:

– ANSYS (linear and non-linear)

– Matlab

– Labview

Engineering Prototyping

Throughout development, iterative prototyping plays a critical role in testing the functionality of a product. With an in-house prototyping shop, engineers work hand-in-hand with prototype specialists to fabricate prototypes in our 20,000 sq. ft. shop. The shop is equipped with machines for casting and molding, machining, metalworking, finishing and painting, rapid prototyping and integration of soft goods or electronic components. This allows us to work quickly; going from 3D CAD to creating parts to assembly to testing all under one roof.

With our in-house prototype shop, Learn More About Engineering Prototyping>

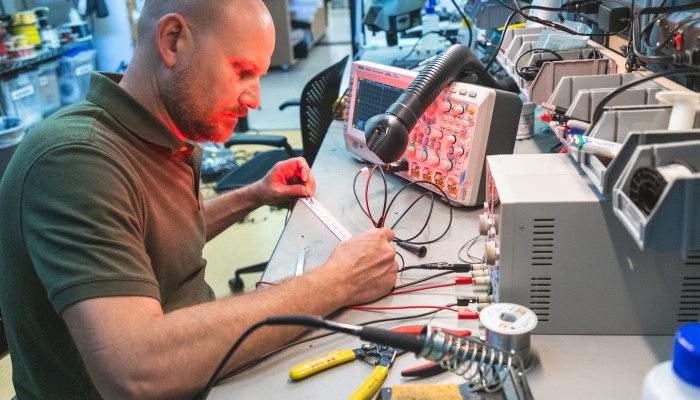

Engineering Testing & Analysis

We have built engineering labs specifically to run calibrated tools or build custom testing equipment. Testing can take place at any point in the development process where results can be used to determine the parameters of the design, set benchmarks, understand performance needs or evaluate the products competitive landscape. Testing needs include: tensile/strength testing, life cycle testing, product performance testing, optimization testing and more.

Throughout the years, we’ve created an air cannon to test impact on materials up to 100 mph, a throwing machine, even set up a motion capture lab to analyze what effects accuracy and speed have on a lacrosse throw. Understanding material and design under specific conditions aids with optimizing design. Once the product reaches early manufacturing, we can also conduct quality or pre-production cycle and product reliability testing.

Learn More About Engineering Testing & Analysis >

Part Fabrication & Assembly

Over the years, we’ve worked on products from simple assemblies to thousands of individual parts. We discuss with our clients the materials and manufacturing methods utilized to help determine the right materials and production needs for each product. If we aren’t the resident expert on the materials you need, we can help connect you to the right resource to keep the project moving smoothly.

Transfer to Manufacturing

When the project is coming to an end and ready for manufacturing, we help clients transfer information, files and facilitate coordination for production.

Often, this includes activities such as detailing of CAD, 2-D documentation, supplier selection, handoff of data, completing first article inspections and verifying assembly fit and finish. We help clients ensure the intent isn’t lost in communication, and that they cross the finish line to a successfully produced product ready for launch.

Learn More About Engineering For Manufacturing >

Engineering Services

Whether You Need Us From Start to Finish or Just One Step, Here's How We Can Help:

Product Ideation

Early on in the process, engineers work alongside design teams on product ideation and brainstorm sessions. With experience across industries, we develop innovative solutions that cross-pollinate ideas from other industries, providing new solutions in unexpected ways. At this stage, engineers weigh in on material selection and preliminary considerations for manufacturing. Initial ideas may start with quick, rough proof-of-concept prototypes to validate before moving further with a design concept.

Software Tools

It is important to verify software compatibility and constraints with our clients to ensure a seamless transition between our engineers and your company’s development team. We know not every client uses the same tool, and we aim to stay flexible to use the right tool for you.

CAD Packages:

– Solidworks (and Solidworks PDM)

– Creo

– Catia

Analysis Software:

– ANSYS (linear and non-linear)

– Matlab

– Labview

Engineering Prototyping

Throughout development, iterative prototyping plays a critical role in testing the functionality of a product. With an in-house prototyping shop, engineers work hand-in-hand with prototype specialists to fabricate prototypes in our 20,000 sq. ft. shop. The shop is equipped with machines for casting and molding, machining, metalworking, finishing and painting, rapid prototyping and integration of soft goods or electronic components. This allows us to work quickly; going from 3D CAD to creating parts to assembly to testing all under one roof.

With our in-house prototype shop, Learn More About Engineering Prototyping>

Engineering Testing & Analysis

We have built engineering labs specifically to run calibrated tools or build custom testing equipment. Testing can take place at any point in the development process where results can be used to determine the parameters of the design, set benchmarks, understand performance needs or evaluate the products competitive landscape. Testing needs include: tensile/strength testing, life cycle testing, product performance testing, optimization testing and more.

Throughout the years, we’ve created an air cannon to test impact on materials up to 100 mph, a throwing machine, even set up a motion capture lab to analyze what effects accuracy and speed have on a lacrosse throw. Understanding material and design under specific conditions aids with optimizing design. Once the product reaches early manufacturing, we can also conduct quality or pre-production cycle and product reliability testing.

Learn More About Engineering Testing & Analysis >

Part Fabrication & Assembly

Over the years, we’ve worked on products from simple assemblies to thousands of individual parts. We discuss with our clients the materials and manufacturing methods utilized to help determine the right materials and production needs for each product. If we aren’t the resident expert on the materials you need, we can help connect you to the right resource to keep the project moving smoothly.

Transfer to Manufacturing

When the project is coming to an end and ready for manufacturing, we help clients transfer information, files and facilitate coordination for production.

Often, this includes activities such as detailing of CAD, 2-D documentation, supplier selection, handoff of data, completing first article inspections and verifying assembly fit and finish. We help clients ensure the intent isn’t lost in communication, and that they cross the finish line to a successfully produced product ready for launch.

Learn More About Engineering For Manufacturing >